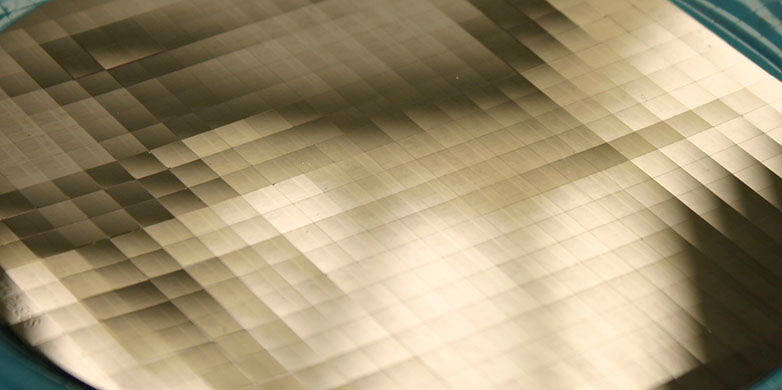

Wafer Cutting

Silicon wafer cut into small pieces lying on a blue tape.

Responsibility:

Disco DAD 3221 Dicing Saw

Technical Data:

- Sample dimensions: up to 6" diameter or 4x4" square

- Thickness: Ceramics up to 1.1 mm, Glass up to 2 mm, Sapphire up to 0.5 mm

- Spindle revolution: 3'000 up to 40'000 RPM

- Kerf width for Silicon 40 microns, ceramics 150 microns, Sapphire 250 microns

- Index position accuracy: 0.005 mm

- All axes fully computer-controlled

- Automatic alignment, automatic focusing, automatic kerf checking, and other image recognition functions

Allowed materials:

- Silicon

- Glass, fused silica

- Ceramics like AlN, Al2O3, SiC, Lithiumniobate

- Sapphire

- SiC

- Other materials only on request!

Not Allowed Materials:

- Toxic materials like InP, GaAs etc.

- Water pollutants like ZnO

- Metal plates

Because the operation of the dicing saw needs regular use and technical skills, only one user per group will get an introduction. This user is in charge for the dicing work of his group.

Responsibility:

- Emilio Gini

- pending

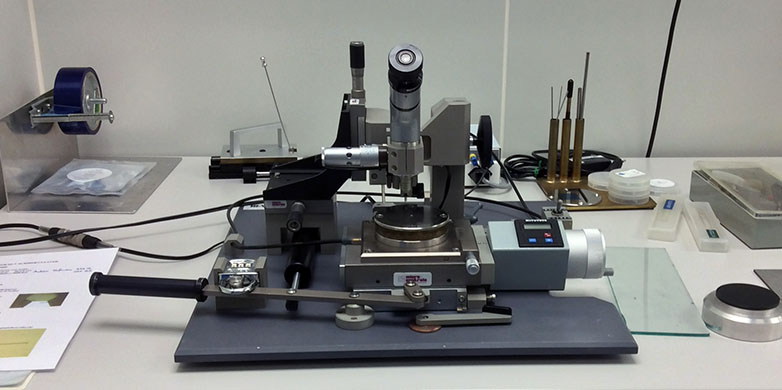

InP Scriber

- Diamond wafer scriber for III-V wafer

- Precision diamond scribe and break tool

- Sample size up to 2”

Responsibility:

- Sandro Loosli

- pending

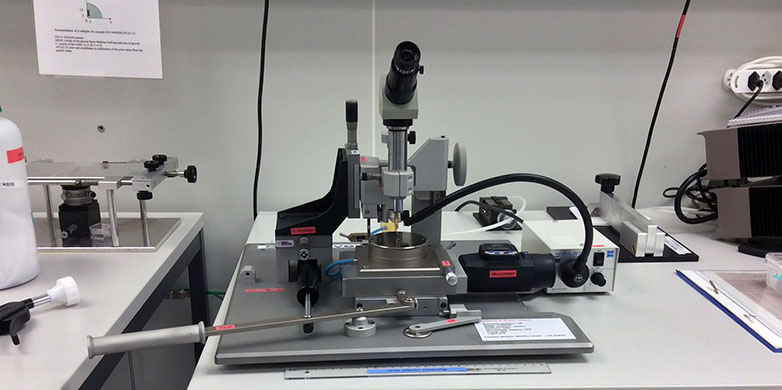

Si Scriber

- Diamond wafer scriber for Si wafer

- Precision diamond scribe and break tool

- Hexagonal diamond 120°