Magnetron Sputtering

Responsibility:

For training (duration: 2 days) or depositions, please fill out the protected page following form and send it to Nensi Toncich. Training is only possible after participation in the FIRST introduction day.

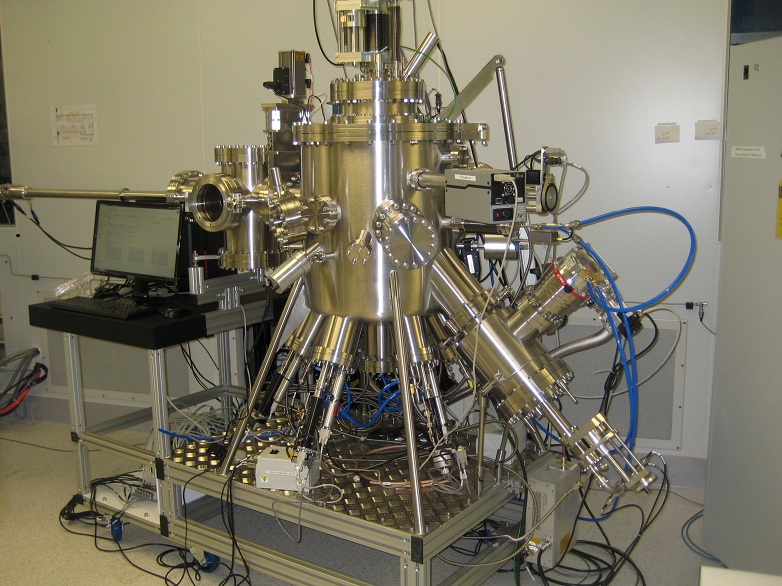

Mantis HiPIMS

- Sputter coating of a wide range of substrate materials like metals, ceramics and polymers

- Target materials: Al, Cr, Cu, IGZO, ITO, Si, Ta, Ti, W others on request

- Confocal arrangement of five sources for creation of combinatorial thin films

- Four 3-inch diameter magnetron sputter sources

- Three 720W DC power supplies units

- One 300W RF power supply unit with matching network

- HiPIMS DC pulsed power supply unit for dense film microstructures (1kW, 0-1kV, 0-100A, max pulse rate 10 kHz). The pulsed source can be used by superimposing a DC bias voltage

- Maximum substrate size: 4-inch

- Maximum substrate temperature: 800°C

- Operating pressure range: 1-12 mTorr in Ar or gas mixture (Ar, N2, O2)

- Mass flow control units: Ar (100 sccm), O2 (100 sccm), and N2 (100 sccm)

- Base pressure of the main chamber: P < 1 x 10-6 mbar

- Loadlock with separate pumping system for fast sample loading

- Nano-particle target for particle co-sputtering (particle size range= 20-200nm)

- Three 1-inch Nano-particle target sources with 3 DC power supply units

- Target materials for nano-particle sources: Al, Ag, Au, Cu, Fe, Ni, Pt

- Residual gas analyzer (RGA)

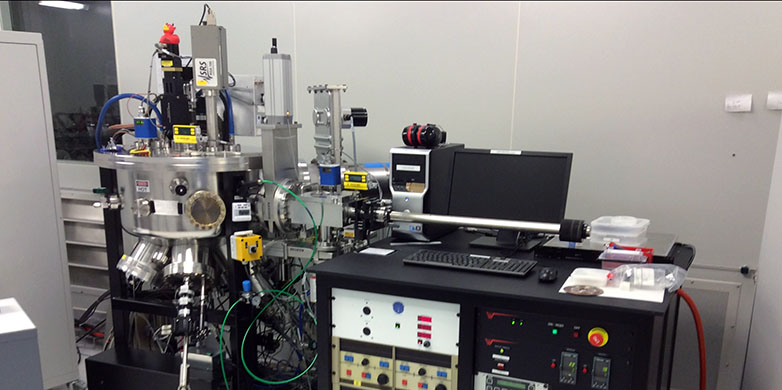

PVD magnetron sputtering

- Target materials: Ag, Al, Al2O3, AlLi, AlMg, Au, Co, Cr, Cu, Fe, FeMnPd, Gd, Ge, ITO, Mg, Mn, Mo, Nb, Ni, Pd, Pt, Si, SiO2, Sn, Ta, Ti, TiN, TiO2, W, Y, Zn, Zr, others on request

- Sputter coating of a wide range of substrate materials like metals, ceramics and polymers

- Confocal arrangement of four sources for creation of combinatorial thin films

- Four 3-inch diameter magnetron sputter sources with 1 spare port for optional sputter source or ion source

- Ion source (KRI - maximum power 1200 eV, maximum current 10 mA) for surface treatment or substrate cleaning

- Four 500 Watt DC supplies and 600 Watt RF supply with matching network

- Maximum substrate size: 4"

- Maximum substrate temperature: 700 °C

- Liquid-cooled chuck (e.g. LN2, water) for low temperature depositions or treatments (quenching)

- Operating pressure range: 1 x 10-3 to 0.25 mbar in Ar gas or mix

- Mass flow control units: Ar (100 sccm), O2 (50 sccm), and N2 (50 sccm)

- Cryo pump: 4,000 l/sec for water (the dominant background gas), 1,500 l/sec for air, and 1,200 l/sec for Ar

- Base pressure of the main chamber: P < 1 x 10-6 mbar

- Loadlock with separate pump for fast sample loading