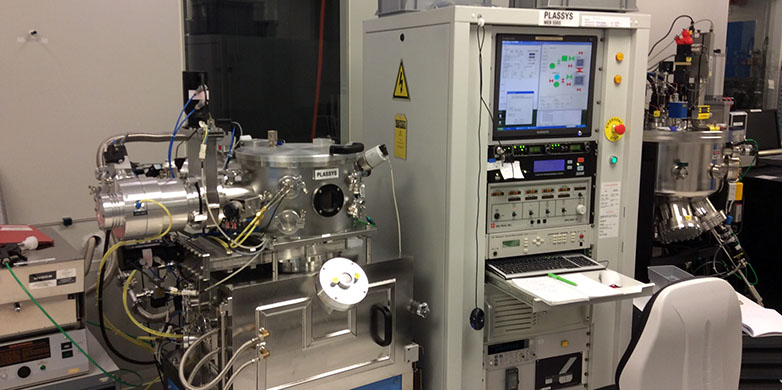

Electron-Beam Evaporation

Responsibility:

- 10 kV 0.6 A electron beam gun

- Base pressure: main chamber below 2x10-8 mbar, loadlock below 1x10-7 mbar, integrated bakeout

- Evaporation of metals (below 1x10-7 mbar) and dielectrics (1x10-6 ..1x10-5 mbar)

- 8 pockets of 20 ccm volume, different liners depending on material

- Materials: *Au* *Ti* Pt Cr Ge Al Ni Pd *Al2O3* *SiO2* In2O3 ITO etc.

(materials *marked* are always present, others may change according to user requests) - Sample size up to 5 inch with uniformity of 5% uniformity over 5 inch, 2% over 4 inch

- Sample holder with tilting

- 6 MHz crystal rate monitor (two crystals)

- Ar sputter ion source with O2 line in loadlock, separated from main chamber